Safety and Quality Improvement

Safety Management

The MIRAIT ONE Group, which builds the infrastructure of society as its business domain, creates value based on the basic premise of guaranteeing and improving safety, and implements business processes that prioritize safety.

Establishment of “MIRAIT ONE Group: Charter on Safety and Compliance”

In July 2022, the “MIRAIT ONE Group: Charter on Safety and Compliance” was established to reaffirm the Group’s priority on commitment to safety as the cornerstone of corporate management. With all employees working in the Group dedicated to ensuring safety and compliance based on this Charter, we aim to create a corporate group that continuously earns the trust of all stakeholders and strive to contribute to realizing a sustainable society.

For Further Improvement of Safety Awareness

For the elimination of accidents and further improvement of safety awareness, the Group reminds its employees of the importance of everyday reflection on basic manners of operation, prepares safe operation procedure manuals, provides safety training, creates videos of accident cases, and is proceeding with the visualization of afety rules. In addition, the Group works to activate communication with workers, econfirm safety awareness, and disseminate safety measures, through frequent visits of management executives including the President to workplaces and annual Safety Convention that involves group companies and partner companies.In the event of a major accident, we promptly hold an Emergency Accident Response eeting, including key Group companies, to thoroughly examine the background and ircumstances of the incident and identify its root cause. Additionally, we establish and mplement Group-wide measures to prevent recurrence, working together across the roup to eliminate accidents.

Danger Simulation Training

We hold “danger simulation training” using VR with the aim of eradicating falling and slipping accidents, which account for approximately 40% of all fatal accidents in the construction industry. The purpose of this program is to increase recognition of the importance of basic movements and fall prevention equipment, and to enhance safety awareness through firsthand simulation of fall accidents.

VR-based danger simulation training

VR-based danger simulation training

Ensuring Safety During Emergencies

To be prepared for large-scale natural disasters, acknowledging the rising importance of our support for the restoration of information and communication infrastructure in the event of a disaster, the Group holds periodic disaster response drills twice a year to learn the principles of actions to be taken in the event of a disaster, safety confirmation methods, methods of gathering disaster-related information. Additionally, since 2023, we have been actively promoting the “MIRAIT ONE’s smart work-lifestyle reform,” while ensuring the effectiveness of safety confirmation systems for flexible working styles such as telecommuting and remote work.

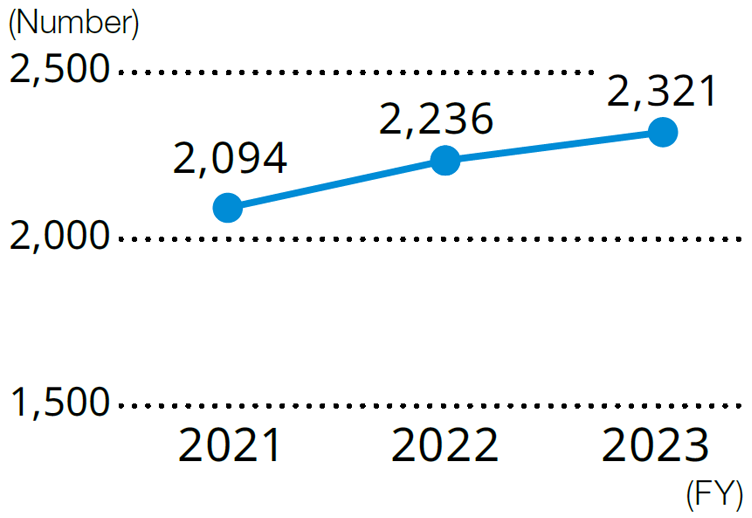

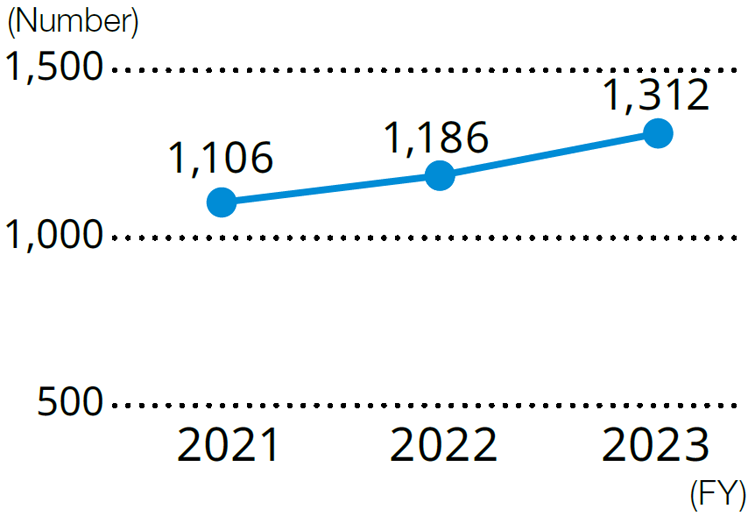

Promoting the Acquisition of Authorization of Workers for High Elevation Work Safety

We encourage our engineers to obtain the “Authorization of workers for high elevation work safety (Access system)” or “Authorization of workers for high elevation work safety (Network system)” so that they can work safely and reliably in high places.

Number of new candidates for authorization of workers for high elevation work safety

(People)

| FY2021 | FY2022 | FY2023 | |

|---|---|---|---|

| Access system | 104 | 109 | 52 |

| Network system | 32 | 64 | 56 |

Training to experience high elevation work

Training to experience high elevation work

Introduction of Cloud-type Drive Recorders

From 2019, the Group uses cloud-type drive recorders for business vehicles in order to eliminate traffic accidents during trips to work sites or other occasions. As of the end of FY 2023, drive recorders have been installed in about 87% of the Group vehicles (approximately 1,900 vehicles), resulting in 8% reduction of traffic accidents (at-fault) in FY 2023 compared with the previous fiscal year.

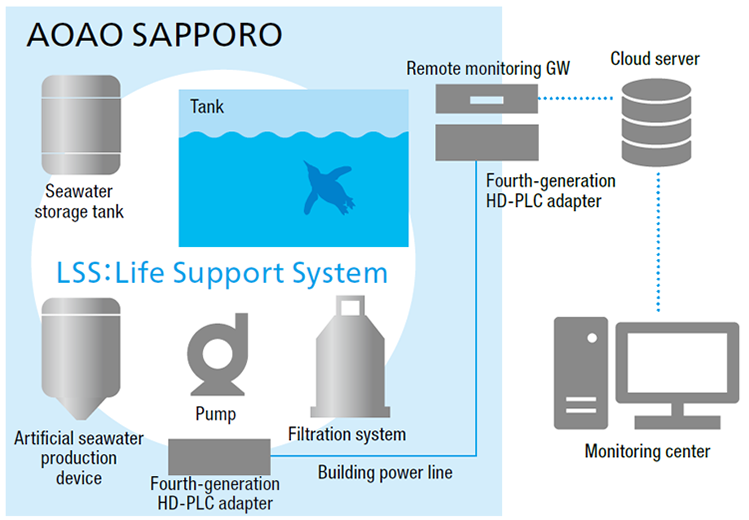

Expansion of Network Camera Installation for Site Monitoring

Our group, leveraging the regional network built over many years, excels in regional revitalization business. For projects in remote or mountainous areas where on-site visits for monitoring involves excessive effort or risk, we have developed a system to provide safe and high-quality services with limited personnel through efficiency improvements using ICT technology.

As an example, in FY 2023, we expanded the installation of network cameras for site monitoring. We will continue to expand this installation in FY 2024, focusing on ensuring the safety of on-site personnel and further improving work-life balance.

Remote monitoring using network cameras

Remote monitoring using network cameras

ISO 45001-Conformant Occupational Health and Safety Management System

We operate occupational health and safety management systems in compliance with ISO 45001. As of March 31, 2024, all business locations of MIRAIT ONE Corporation are certified.We comply with laws and regulations as well as occupational safety and health requirements, reduce and eliminate occupational safety risks through risk assessment and activities to anticipate danger, and promote safety and security through educational exchanges in accordance with the Policy on Occupational Safety and Health, which explicitly names safety as the highest priority in operations. We continuously improve our performance by identifying all actions that can lead to accidents resulting in injury or death, serious traffic accidents, and other seriously unsafe incidents as supervision check-points.

Quality Management

The Group considers quality as important a business challenge and source of competence as safety. The “MIRAIT ONE Group: Charter on Safety and Compliance” reaffirms “quality assurance” as a material issue and emphasizes the commitment to “constantly incorporate new technologies and provide high-quality, superior deliverables to meet customer expectations.”

Improving and Maintaining Technical and On-site Capabilities

The Group implements training and a technical certification system to steadily improve and maintain its technical strengths that support service quality.

In recent years, worksite supervisors* who play the important business role as the representatives of work sites are required to have a wide range of skills to deal with the increasing number of construction projects and the diversification and growing complexity of construction projects. As a concrete measure for such a situation, the Group carries out “Worksite Supervisor Training” for newly appointed worksite supervisors and deputy worksite supervisors.

* One of the supervisory positions appointed by the Group to oversee individual works.

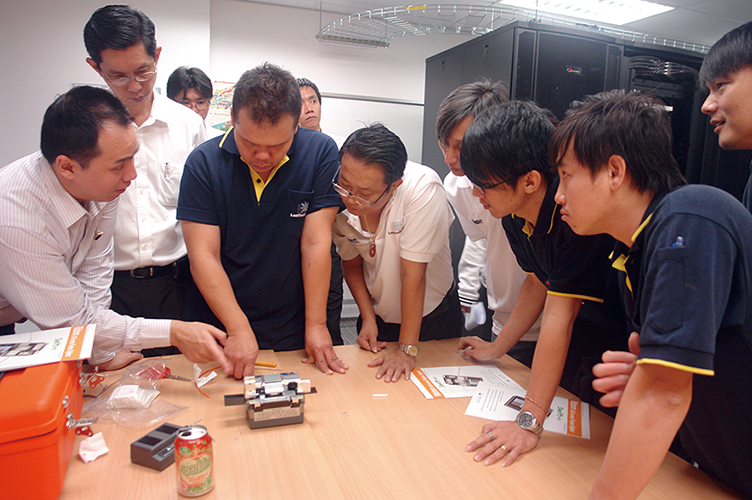

The Engineer Training Subcommittee, aimed at developing specialized technicians, offers various training programs for employees of the Group and partner companies.

Especially, 1,753 employees have received the mobile skill training to build their skills since the start of training in 2010.

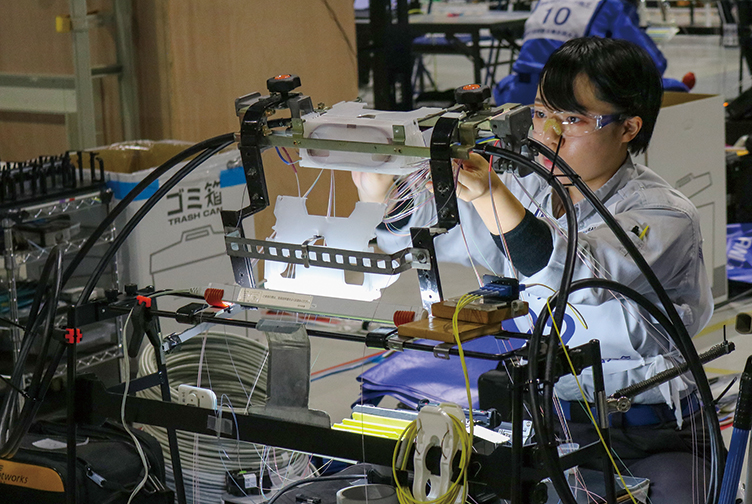

Additionally, we participate every year in the “National Skills Competition” organized by the Japan Vocational Ability Development Association. At the 61st competition held in November 2023, our employees received a Medallion for Excellence in “Information Network Cabling.” We will continue to improve our technical capabilities through participation in competitions and other means to offer and maintain safe, reliable and high-quality services.

Our medal-winning employees

Our medal-winning employees

ISO 9001-Conformant Quality Management System

We have established and are operating a quality management system in accordance with ISO 9001, and our Quality Policy stipulates “swift response to legal regulations and customer demands,” “raising customer satisfaction by enhancing the quality of products and services as well as construction (while realizing efficient production and services),” and “maintaining and improving QCD through quality risk reduction.” Specific processes, procedures, and decision criteria aimed at achieving the policy are defined in internal rules and regulations.

Additionally, mobile terminals are used in checking and verifying the quality of the respective tasks. Also, the achievement status of targets set by each group company based on the nature of their business (number of facility accidents, number of problems reported after inspection, customer satisfaction evaluation score, etc.) is reviewed for reflection in the subsequent fiscal year and beyond.